FacilitiesTechnology and quality

The combination of our technical expertise and track record, acquired over many years, ensures that the ADCLEAN series always provides our customers with the highest quality products.

In manufacturing the ADCLEAN series, we make full use of high tech materials, designs that bring out the best performance, and the most precise sewing techniques. Then, after testing in our state-of-the-art clean rooms room, we are finally ready to go into production.

Our evaluation testing is carried out by the most highly skilled experts, and we collect and analyze detailed data from every angle through visualization tests, tumbling tests, friction-charged voltage tests, dust generated by movements test, etc. Accurately reflecting these data in our products enables us to manufacture goods with the high degree of functionality that our customers demand.

In order to quality deliver peace of mind, we also conduct tests to determine how much our garments deteriorate over time, as part of our after-sales service. Many of our customers are pleased with our operational support system that helps keep clean rooms in optimum condition.

ADCLEAN products are imbued with technology that is supported by imagination, people, and facilities.

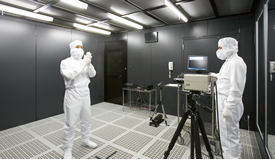

Visualization tests conducted in our own black room

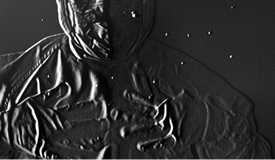

Visualization test

To enable us to visualize the process of dust generated during movement in our own facilities, we established a black room outfitted with a high precision “ultrafine particle visualization system”. Technology for creating powerful, uniform optical sheets (green laser) and camera technology that enhances faint scattered light permit ultrafine particles (PSL particles) to be perceived with the naked eye.

These data permit the recording and analysis of dust emission in a variety of positions arising from every conceivable movement inside the clean room. They are used in the development and improvement of thoroughly dust-proof garments based on dust-generation mechanisms.

Evaluation testing conducted in our own clean room

Tumbling test

Test products are put into the tumbler and rotated at a constant speed, causing dust to be generated. Air samples are drawn from inside the tumbler and the particles are measured.

Friction-charged voltage test

Artificial frictional electrification is induced and potential attenuation is measured.

Test for dust generated during movement

A number of movements are undertaken while wearing a clean suit. Air samples are drawn and the particles are measured.

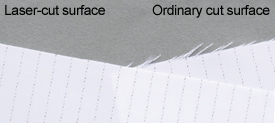

Proprietary laser cutter

A state-of-the-art laser cutter was introduced to provide even higher quality products. This prevents fiber loss from the cutting surface, which is the source of dust.